Overview

Automotive manufacturing is a major driver of Industry 4.0 (I4.0) technologies and of

economic wealth in industrialized countries. Although the main sources of professionals

for this industry are still universities and research institutes, teaching and training have

not kept pace with the advances in technology.

This is an important disadvantage, as engineering and manufacturing learning and knowledge transfer require innovative practices and technologies to support current I4.0 ventures.

The COVID-19 pandemic made this disadvantage evident, as many universities or learning centers lacked the technological infrastructure and educational practices to overcome the unprecedented measures to reduce contagion risks (i.e., human isolation and safe-distance interaction). This further complicated the traditional knowledge transfer processes in the automotive manufacturing and production fields, which require physical prototyping of mechanical components and laboratory-assisted testing. In this regard, aspects of Industry 4.0 such as virtual environments and enhanced human–computer interaction could have been important resources to improve teaching practices and achieve the equivalent Education 4.0 (E4.0) paradigm.

Although Industry

4.0 aspects have been deployed within the automotive industry, educational institutions

are striving hard to adapt to this latest industry trend. Specific courses and majors

such as those in medical, technical, and engineering subjects cannot be addressed through standard e-learning tools. In this case, I4.0 technologies of augmented and virtual reality

(VR/AR) can provide the required in situ user experience for practical learning.

Hence, updated teaching processes and infrastructure are needed in universities and VET centers to

move the professional student (physically and/or virtually) closer to industrial practice,

generate new knowledge.

2. Automotive Industry in terms of Industry 4.0

Through digitization and automation of the production processes within the factory,

I4.0 can integrate different technologies in a cyber-physical network to reduce costs and

improve market response and resilience. This implies a redefinition of the production

processes without overlooking the requirements of cost reduction and early market deployment as new competitors emerge.

The four main characteristics of I4.0 that must be considered in designing and developing such factories are: (1) vertical networking of production systems, (2) horizontal

integration of global value-chain networks, (3) end-to-end engineering of overall value

chains, and (4) the use of high-impact disruptive technologies.

Disruptive technologies encompass artificial intelligence (AI), augmented reality (AR),

and 3D printing, and they include a significant use of smart systems such as collaborative

and specialty robotics, advanced sensors and microsensors, and automation components

for microprocessors and microcontrollers.

Virtualization technology involves the creation of a “digital twin”, based on creating

virtual models of real systems and digitizing physical objects to simulate their behavior.

These virtual models are capable of understanding the state of physical entities through

data detection, to predict, estimate, and analyze dynamic changes, where physical objects

respond to changes according to an optimized simulation scheme. Finally, virtual

reality and augmented reality (VR/AR) enable human–machine interaction systems that

fulfill three basic features: a combination of real and virtual worlds, real-time interaction

via online platforms, and accurate 3D registration of virtual and real objects. In VR/AR,

the virtual–digital model is capable of being controlled in the same way that the physical

model would be, and in addition, the latter must respond to the changes made in the virtual

model. In particular, VR/AR is an interactive experience of a real-world environment where

the objects that reside in the real world are enhanced by computer-generated perceptual

information, sometimes across multiple sensory modalities including visual, auditory,

haptic, somatosensory, and olfactory.

3.Digital technologies in Education

In recent years, rapid developments in communication technologies and computer systems have given rise to innovative multimedia formats suitable for distance education. In addition, the development of radio-to-audio/video broadcasting, teleconferencing, computer-assisted instructions, e-learning/online learning, podcasting, and VR/AR has led to these elements becoming attractive for the generation of new teaching strategies. In this regard, digital technologies play an important role in the learning process, not only facilitating the assimilation techniques for various theories and elements of the respective engineering areas but also the assimilation of knowledge about new techniques for specific industries such as the automotive, aerospace, and aeronautic industries, among others.

New skills and competences must be acquired among students in the areas of computer-aided design, manufacturing and engineering (CAD/CAM/CAE), and digital manufacturing, as well as in different fields of specialization such as simulation of processes and physical phenomena. In addition, 3D drawing training is useful, especially when analyzing situations beyond design such as simulating flow and making/testing product prototypes, as it offers more precision and control. Furthermore, 3D CAD drawing skills are useful.

4. VR/AR Technologies for Education

To introduce students properly to many relevant I4.0 elements, teaching and training in specific fields of study should be oriented to specific topics such as simulation studies on real-time data and optimization, AI, BD, enhanced productivity education on additive manufacturing and advanced robotics, maintenance/logistics studies through augmented reality, and evaluation studies on the environment, society, and economics . Within these topics, AR involves an alternative method for perception of the surrounding real world. This is achieved by using virtual elements superimposed through various technological devices such as smartphones, tablets, or virtual reality devices.

Moreover, VR is defined as the development of simulated experiences similar to real-life situations. It is worth mentioning that the impact of both AR and VR has increased in the last decade with the advanced development of computer systems. Improved VR/AR is being used in the early stages of product development and the construction and validation of prototypes . The virtual framework enables the generation of data which can be shared and continuously reviewed by work teams through cloud-based systems. VR/AR technologies are valuable tools not only in the design stages but also in the training of operators in assembly processes, allowing safe interaction with the product prior to commissioning. However, the use of VR/AR technologies for industrial and educational activities requires important guidelines and protocols. In this regard, the ISO/IEC TR 23842-1 standard was released in 2020, as a standard establishing guidelines on information technology for education and training based on the use and creation of VR content and applications. These guidelines are aimed to prevent issues associated with the use and development of VR technology and content such as:

• Discomfort (i.e., dizziness, headache, nausea) caused when actual physical movement does not occur with respect to the visual stimulus generated in the virtual environment. This is also known as VR/simulator/motion sickness or “cyber-nuisance”.

• Eyesight problems (i.e., visual fatigue, blurred vision, mechanical near-sightedness) due to the proximity of the VR hardware to the user’s eyes. • Photosensitivity syndrome, where seizures (epilepsy) occur due to rapid flashing light stimuli.

• Musculoskeletal disorders (i.e., pain or fatigue of the musculoskeletal system) due to performing repetitive tasks over long periods of time while using VR hardware. • Hygiene problems (skin and/or eye infection/irritation) due to poor disinfection or cleaning of the VR hardware, which is used by many people. Appl. Sci. 2022, 12, 5993 5 of 13

• Accidents (i.e., collisions, falling) caused by the limitation of the user’s field of view when using VR devices. These accidents may also occur when the user confuses reality with the virtual world (e.g., when users try to sit or lean against a virtual-world chair or wall that does not exist in real life).

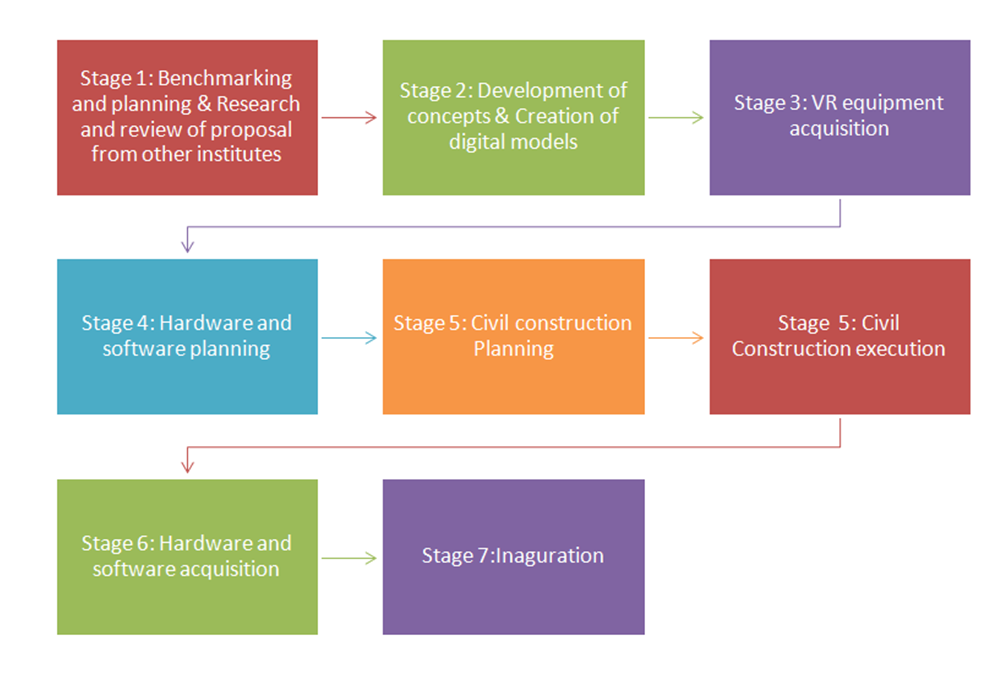

5. Development of the Virtual and Digital Laboratory: stages of the Planning Process.